Michiana Rotational Molding Constantine Michigan

Michiana Rotational Molding Services

R&R Technologies LLC is a leading provider of Michiana rotational molding for southwest Michigan. We have over 50 years of Michiana rotational molding experience, ranging from automotive and truck to lawn and garden, waste management, portable containers, and more. Our customers value our full in-house service, which includes sales, engineering, and design development. We provide design support for design as well as mold design. Our mold capabilities allow us to build molds faster than our company. We pride ourselves on being the go-to rotational molder for engineered plastics, including polycarbonates, polypropylene, PVC, and Acetal. Michiana Global Mold has stood behind its processes since 1966 by offering leading warranties which are the best in the business. Our dedicated staff brings over 500 years of combined experience solving problems with rotationally molded items. In addition, we offer design development and manufacturing. Our customers value our close relationships with them as we help them meet the needs of their items by working closely with them to understand those needs and develop results that exceed their expectations. We have over 50 years of rotational molding experience in industries ranging from automotive and truck to lawn and garden to waste management.

Michiana Rotational Molding Constantine Michigan

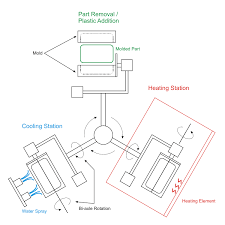

Rotational Molding is a plastic process that involves heating and cooling plastic resin in a mold under high pressure. The resulting parts can be made out of one or multiple materials, creating various shapes. Including flat sheets, hollow tubes (cans), large shells for boats or other transportation use (automotive bumpers), containers for food items like takeout containers used by restaurants around the world...the list goes on! Rotomolding offers unique capabilities because it's such an efficient process; this allows manufacturers who use rotational Molding to make items faster than traditional processes like injection molding. However, it requires more energy consumption during heating up time before being able to produce its parts efficiently enough per hour time frame required for some large scale production runs."

Rotational Molding Near Me Michiana

Our customers value our sales, design development, and manufacturing. It gives us the ability to provide design support and mold design. Our design department has extensive experience with a wide variety of materials that helps us provide top-notch customer consulting during the quoting process and during production. We provide design support as well as mold design. If you are new to rotational Molding, we can help. We provide design support as well as mold design. The usual way for a customer to approach this process is by working directly with our technicians in the beginning stages of creating their project and then handing off the final piece to us at a later completion stage. It helps us to understand your needs and get a clear picture of how best to handle them based on the details you provide or your organization's representative(s) provide.

Michiana Rotational Moulding Cost

When designing molds and items together, there are multiple options available from which you may choose. Designing A Mold And Product Together (Similar To Design Briefs)

This method requires that both aspects be thought through simultaneously because they will influence each other greatly throughout development. It can mean more work upfront but gives better results by decreasing risk later on when producing your final result! Designing a mold and product separately allows more flexibility in choosing materials/colors/finishes. It depends, though, upon what type of part it will be used for initially since they won't affect each other directly until they're being produced together. At some point down the line here, after having been separated firstly into two separate forms, one being molded parts made from polystyrene foam blocks using either solvent casting techniques or liquid silicone rubber molds using vacuum chamber curing methods instead. Our mold process capabilities allow us to build molds faster than other U.S. competitors. We have in-house mold production capabilities, which means we can build a mold faster than our competitors. Our dedicated team of designers and skilled machinists work together to create the best possible molds for your company. We also have a full-time quality assurance department that tests every part before it leaves our facility. As a result, Michiana rotational molding provides the best quality molded parts on the market today! With our expertise, we will solve problems with rotationally molded ones, no matter what they may be!

Michiana Rotomolding

We pride ourselves on being the go-to rotational molder company for plastics, including polycarbonates, polypropylene, PVC, and Acetal. Polycarbonates, polypropylene, PVC, and Acetal have a wide variety of applications and can be found in industries such as automotive, medical devices, and industrial equipment. Rotational Molding is a great solution when you need high-quality complex design requirements that other molding methods cannot meet. Rotomolding also provides excellent benefits over other processes like casting or forging because it allows us to create parts with complex shapes that are hard to form by any other means.

Michiana Rotational Molding Constantine MichiganMichiana Rotational Molding Options

Michiana Rotational Molding offers industry-leading warranties, which are the best in the business. Lifetime Warranty: All molded parts are covered for life against defects in material and artistry. 25-Year Warranty: All molds are guaranteed free of defects and will be repaired or replaced at no charge if they fail during everyday use. All parts have a ten-year warranty against material and quality defects while being used as intended. However, this does not cover damage due to misuse or abuse (such as allowing water to enter your part's cavity) or failure caused by improper maintenance practices (such as over-tightening screws). In addition, parts carry a five-year warranty against material and quality defects while being used as intended. However, this does not cover damage due to misuse or abuse (such as allowing water to enter your part's cavity) or failure caused by improper maintenance practices (such as over-tightening screws). Our dedicated employees bring over 500 years of combined experience solving problems with rotational Molding. During their careers, they have developed a deep understanding of how items are made and how they can be used. It allows them to analyze issues in a way no one else can and find practical solutions.

Michiana Rotational Molding Constantine Mi

We offer various mold design options and work closely with you to create the best possible solution for your unique application. Our experienced machinists can produce molds from various materials, including steel, aluminum, and plastic. In addition, we can provide our process services if your part requires intricate details or high tolerances. Mold testing is another option available through Michiana rotational molding's processes; every mold must be analyzed before use to ensure that it performs appropriately when casting parts. We also provide mold repair for any defects or damage sustained during use by clients. In addition to repairing existing molds, we also offer maintenance plans that include regular inspections and certifications and training programs for employees charged with operating curing ovens or injection machines equipped with these custom-built tools! Rotational Molding is a method that uses heat and pressure to create hollow plastic parts. Rotational Molding is used in automotive, lawn and garden, waste management, portable containers, and more. R&R Technologies LLC provides Michiana rotational molding options for southwest Michigan. In addition, we provide design development for our customers around the globe. We pride ourselves on being the go-to rotational molder for polycarbonates, polypropylene PVC, and Acetal.